The Action Shot is of the Kapsules, hammer Beeks, and Damper Lifters in the 1835 Graf Fortepiano in Ann Arbor, Michigan

Harpsichord after Johannes Petrus Bull in Antwerp 1789 made by Keith Hill Opus 57 in 1978 revised in 1988.

My treatise on The True Art of Making Musical Instruments—A Practical Guide to the Hidden Craft of Enhancing Sound is now published and available on Amazon.com. Here is the link for that page.

https://www.amazon.com/dp/1791889611

There has never been a book written that covers the craft of enhancing sound until now. Indeed, most books written about sound are based on the physics of sound. In the 47 years I have been making musical instruments, I have never found it either necessary or useful to know anything about the physics of sound. My reason for this total disregard for such knowledge is that ALL the greatest musical instrument makers from 1400 to 1840 including Stradivari, Guarneri del Jesu, Amati, Ruckers, de Zentis, Blanchet, Taskin, Cristofori, Stein, Hubert, Walther, Graf, Schnitger knew nothing about the physics of sound. That is because all such knowledge wasn’t discovered yet. What these makers knew was vastly more important and valuable, that is, the science and craft of enhancing sound, all knowledge of which, unfortunately, was secreted away only in their instruments.

Now, some people quibble with what I have just written, so in response I would like to have proof where researchers in the area of the physics of sound have figured out how to increase the clarity of the sound of an instrument, increase the immediacy of the sound of a violin, increase the depth of sound, increase the intensity of sound, increase the carrying power of the sound of an instrument, increase the vocal property of a sound, increase the evenness of sound from bass to treble of an instrument, increase the ease of recording quality of an instrument, increase the responsiveness of color flexibility while playing the instrument, increase the ability of the sound to bloom in an instrument, increase the perceptibility of pitch in an instrument, increase the ability of the instrument to reflect the intentions of the player, and last but not least, increase the ability of the sound to capture the listener’s attention. Each of these qualities are what the ancient instrument makers knew how to build into their instruments and it is precisely these qualities that remain beyond the ken of scientists and makers who fancy themselves as acoustical scientists. It is these qualities the knowledge of how to build them into a sound that is secreted away in their instruments. The only scientist I know of who made some progress in tackling these qualities was Jack Fry, but he succeeded by the same approach I myself used for the last 45 years.

My attitude when I began making musical instruments in 1972 was to restrict myself to only that knowledge available to those great musical instrument makers. That body of knowledge, which was acquired over a period of 350 years, had as its foundations the teachings of Pythagoras. Based on his ideas of the musical ratios, makers of all kinds instruments developed the craft of enhancing the sounds of their materials to make their instruments sound as beautiful and as resonant as possible. Then, towards the end of the 18th century, with the development of modern scientific methods and attitudes, all that lovingly acquired ancient Pythagorean based knowledge was put aside and immediately forgotten. Even Conrad Graf in the beginning of the 19th century had to relearn that body of knowledge to produce the sounds of his pianos. But little of what Graf had learned was acquired by apprentices in his workshop. Recovering all that lost knowledge was my goal.

This treatise is meant to preserve this knowledge of how the greatest instrument makers in history thought about sound and how to enhance it.

LIST OF CONTENTS

THE TRUE ART OF MUSICAL INSTRUMENT MAKING

AREA TUNING THE VIOLIN

HINTS FOR AREA TUNING THE VIOLINS

RECIPE FOR MAKING "HILL" VIOLIN VARNISH

RECIPE FOR MAKING "HILL" VIOLIN VARNISH (IN RUSSIAN)

VIOLIN VARNISH DRYING CAROUSEL

ON VOICING AND REGULATING REAL QUILL

ON VOICING AND REGULATING THE HARPSICHORD

THE 1658 DE ZENTIS HARPSICHORD: A RESTORATION

ACOUSTICAL TECHNOLOGY TRAINING

ITS ABOUT PEDAL HARPSICHORDS

It is a sad fact that all previous pedal harpsichord designs mimic the pedal piano designs from the early 19th century. A litany of problems that plague that antique design are listed below. I invented my design in 1980 expressly to solve those age old problems:

A: the problem of tuning the pedal harpsichord (previous designs lay flat on the floor and are as wide as the pedalboard—meaning you have to have help to tune the pedal harpsichord as it can’t be tuned by the person sitting at the manual harpsichord). My design allows the player to sit at the manual harpsichord and easily reach down to tune the pedal instrument.

B: the problem of excessive energy dissipation that results in an unfocused sound in every preceding design. The previous designs being as wide as the pedalboard meant that the soundboard had to be equally wide…too wide to have any significant focus to the sound coming from the pedal instrument.

C: Again, the width of the instrument in the previous designs from the 19th century and on is too wide to fit into a normal van, which makes it a problem to transport the instrument,

D: Because the instrument is within easy reach from the bench, means that the problem of regulating and voicing the instrument is easier.

E: Then there is the problem of supporting the manual instrument above (not a problem for the 19th models intended to fit under a 6 ½ oct. fortepianos but a definite problem for harpsichords which are narrower than those pedal board width pedal harpsichords).

In fact, it is a perfect design and I expected other harpsichord makers to copy the design, naturally, without asking me or giving me credit for the design when they did. But back in 1992 the folks at Hubbard Harpsichords Inc. even had the gall to claim that they had invented the design.

KEITH HILL OPUS 146 - - 16’ HARPSICHORD AND PEDAL HARPSICHORD ENSEMBLE . DECORATION BY KEITH HILL

AREA TUNING THE VIOLIN

by Keith Hill©2015

Originally published as Guild of American Luthiers Data Sheet #283, 1984

Announcements of “discoveries'' of the “secrets'' of Stradivarius usually are not worth the ink used to print them. When they appear, everyone reads them with the customary curiosity. Then away they are filed along with the hundreds of other such claims. They get dredged up again when someone writes yet another book on the violin. Mindful of this possible fate, I would like to offer an explanation of a discovery that I have made. It is not of the “secrets'' of Stradivarius; rather it is, I believe, the acoustical system used by the ancient Italian violin makers to construct the sound of their instruments.

The system is simplicity itself. It is possible for anyone who understands it and has normal hearing to use it. Moreover, it requires no measuring equipment save the ears and possibly a monochord. Furthermore, the thicknesses and their inexplicable variants, which so annoy our modern sense of decency when we observe them in the finest violins by Stradivari and Guarneri, occur naturally as a result of this system. Because it is so simple, it is, of course, the last place one would think to look for the answer. I expect that once you are equipped with the following information, you will go to your nearest antique Italian fiddle and look to see if what I am saying is actually there.

The heart of the acoustical system is this: Each discrete area of vibrating surface on the plates is tuned to an overtone in the harmonic series. In Figs. 1a and 1b you can see how I have observed the areas to be. Not every maker would have used exactly the same distribution. Camilli, for instance, creates many more than the normal areas which I have shown. But for the greater number of makers, what is indicated is what you can notice.

What does this mean?

Take as your fundamental, or first partial, the basis pitch which you have preselected and tune the largest area to it. On the top of the violin, this would be the lower bout on the treble side. On the back of the violin, it would be the lower two-thirds of the lower bout area. All other areas on the plates are tuned to these pitches respectively. The idea the ancients must have understood is: the larger the surface area on the plate you give to an overtone the more prominent that overtone will be to the ear when the violin is finally sounding. The overall pitch of the plate is indicative more of the inherent properties of the wood and is not really relevant. Figs. 2a and 2b and 3a and 3b show typical tuning schemes.

In the violin diagrams below I have abbreviated the names of the pitches in the various areas. So you don't have to puzzle over what those abbreviations mean I have provided a table below.

Fundamental is the beginning or lowest pitch

3 rd is a Third or Tierze above the fundamental

5th is a Fifth or Quintabove the fundamental

8va is an Octaveabove the fundamental

7th is a Seventh above the fundamental

AUG 4th is the Augmented Fourth above the fundamental

s. 8va or s. 5th indicates a Super (above) Octave or Super Fifth meaning an octave higher

4th indicates a Fourth above the fundamental

2nd indicates a Second above the fundamental

2nds and 3rds are labeled as either MAJOR or MINOR

a

It is important to remember that each maker would have had his or her own personal scheme or pattern of ratios. Some might have more than one. Stradivari changed his scheme twice (but with a few variants now and again), his first system being the same as that of Nicolo Amati, his teacher, and the second system being that of his Golden period (see figures 6 and 4). Other makers changed the scheme from instrument to instrument, depending on other factors such as wood quality and the modeling. I have seen only a few Guarneri violins and each has a different scheme and pitch. He clearly understood the relationship between specific wood qualities and things like modeling, pitch selection, and tuning scheme.

As for the question of what pitch to select, that appears to be a matter of personal preference. The usable pitches range from C# to F#. When lower than C# the plates get too thin, and when higher than F# the plates become too thick to resonate freely. Some makers made the top plate higher in pitch than the back and others made the back plate higher than the top. There is no obvious rule, therefore it is probably hidden within the woods used. Stradivari, in the instruments which I have personally inspected, used D for the top and E for the back. Guarneri was inconsistent, for I have seen instruments by him which range from C# for the back and D for the top to F# for the back and F for the top.

After having used this area tuning principle for almost twenty instruments, it is clear to me that some schemes work better for particular pitches while others work best with altogether different pitches. Although the subject is too complicated to discuss in detail here, there is a definite relationship between the fundamental pitch used for the tuning scheme, the scheme itself, and the modeling. While the tuning scheme and the pitch on which it is based are important, unless you strive to make the actual tuning as flawless as is humanly possible, they seem irrelevant. Choose one and make it a pure as possible.

The most important aspect of the use of this area tuning principle is achieving an extremely accurate tuning. Accurate tuning ability seems to be the factor which separates the best violin makers of the period from the mediocre ones. Stradivari and Guarneri were the best tuners. Their ability to tune the wood accurately was unexcelled. This was the heart of their craft. If there is a catch to using this principle, this is it.

It took me about twenty-five instruments to refine my own level of control over the tuning process. I hope that it will require far fewer for those of you who are willing to look into this principle and try it out for yourselves. Because you need not look for the principle, I expect that you can be successful in only five or six tries. I hope that I am not wrong about this. I feel confident that those who are persistent in their pursuit of control over this principle will be successful in producing violins equal to the ones made long ago by the Italian masters.

Any success in acquiring control regarding the use of this principle can be heard. When you get the overtones right, the violin will produce a sound of greater strength of tone, more beauty of sound, better carrying power, and more flexibility. No attempt to tune means leaving everything up to chance. When the attempt has been made and is less than accurate, the result is less open, less free, and less brilliant. When no attempt has been made, the result ranges in sound from muffled to raw and harsh.

The violin sound that results from tuning the plates as I have suggested is at first in need of playing-in. At once the sound is radiant, alive, and feels very healthy. What is lacking is the richness and depth that comes from being played-in. It seems that when a tuned fiddle is played-in it becomes more resonant, brilliant, flexible, easier to play than at first, and deeper sounding. What happens to the wood with playing-in is that the tuning gets clearer and more obvious. The principal effect appears to be like the effect which exercise has on the human body. A noticeable difference in the sound can be observed after only three months of playing-in. I have observed radical differences after a year’s worth of playing-in. What is sure is that when the instruments have had the tuning principle applied to them, they start life sounding wonderful and proceed to become better and better with age and playing-in.

Curiously, there are many people in the violin world who reject a new good-sounding fiddle because of the preconceived notion that it will somehow deteriorate in quality. Where this may be true for instruments which have not been tuned according to the area tuning principle, it is quite the contrary for instruments which have been well tuned. After all, Stradivari’s instruments were much sought after when they were new because of their gorgeous tone quality and their flexible playing properties.

I feel that it will be helpful to include some specific tuning schemes which I have observed in some antique Italian instruments. You can notice the similarities and differences between them at once. As I stated previously, there is a relationship between the modeling on a violin and its specific tuning scheme. Because I can not present in this article the information regarding the modeling, I caution you not to take these schemes at face value. Think of them only as specific schemes for given instruments. That is, they are just a point of departure for thinking about the principle (Figs. 4, 5, 6, 7).

Each maker possessed a different understanding of the variables involved in the execution of his craft and created a tuning scheme to compensate for acoustical inadequacies. In this way, each maker was able to make a sound which felt complete for him. The great makers who extended the acoustical range of the violin felt more compelled to use other methods to reach those same goals as did early makers or makers of less importance to us today.

What I like about the area tuning principle is that it allows every maker to construct a sound which most pleases him. (I don’t really believe that today violin makers everywhere will go and do this, but the spirit of the early Italian masters requires that the idea be suggested.) A maker can do this by designating the largest areas to the overtone he or she most prefers to hear in a sound. For me, there is one instrument that I have heard which feels the most complete. That instrument is the 1734 Guarneri “del Jesu”, known and the ‘Gibson’, owned by Ruggerio Ricci. It has been a challenge to understand that particular instrument. I hope that each one of you will find the one fiddle that challenges you. And, in the same way, I hope that you will try to understand it and aspire to make instruments of a quality equal to it. To do this you need to be able to hear the tuning scheme used by the maker.

Testing a Violin to Notice its Tuning Scheme

For the novice, getting someone who owns a great violin to let you handle their prize for ten minutes may be difficult. I appeal to those of you who are players, who own a great fiddle, to encourage your local maker to listen for the tuning on your fiddle. But for the novice, it may prove advisable to do the listening test with a player or the owner. It is actually easier to hear the overtones that are on the violin plates when someone else is doing the work. I have always found players with such instruments to be very obliging when they understand that no harm can come to their instrument from doing the test.

The actual job of testing the fiddle is easy. But care must be exercised when handling something as valuable as a Stradivari or Guarneri violin. Remove rings, watches, and bracelets from your hands and wrists. The purpose of the test is to discover the tuning scheme by rapping very lightly on the plates. To do this effectively, you will need to damp off any extraneous vibrations or resonances which might complicate the act of listening.

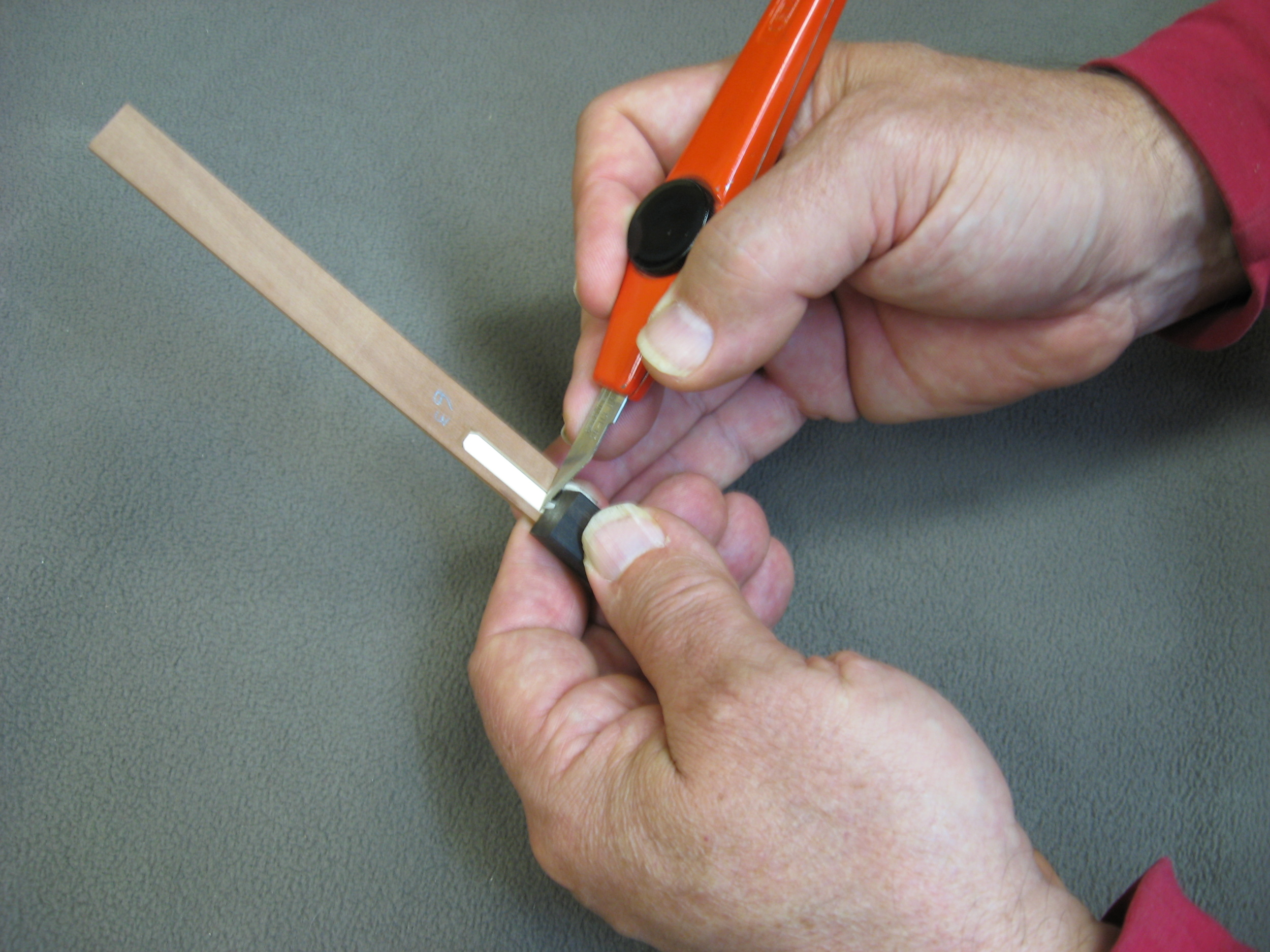

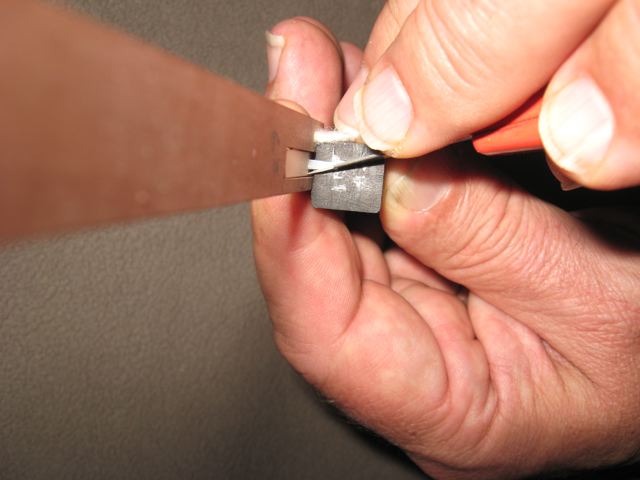

* OOT = Out of Tune

I usually begin with the top. I spread a soft cloth over my lap and lay the violin back side down in my lap. This damps off the back while I listen to the top. I grasp the neck of the fiddle to secure it and to damp off the sound that the strings might make. Using the knuckle on my right hand middle finger (this gives me the clearest sound) I rap lightly at points central to the discrete area I am testing.

The most important part of the test is to establish the interval relationships between the overtones on the various areas. From this you can readily determine the pitch on which the scheme is based. I start with the area in the lower treble-side bout. Progressing to the upper bass-side bout, then to the lower bass-side bout I end up on the upper treble-side bout. This way I establish the basic framework to the tuning scheme and move on to the smaller areas once this framework is established. I find it hard to determine anything about the tuning on a plate when I knock the areas in an isolated way. I zero in on the scheme by checking the relationships between the areas. I will knock here twice, then there twice, then over here and so on. By moving around quickly from area to area you avoid listening too carefully. In the best instruments the scheme will become clear with just a few rappings. In the poorest instruments there will be nothing but out-of-tune areas and no clear relationship.

Many of you will experience the same problems hearing the tuning that I had. Trying too hard is a big one. If you assume an almost casual attitude when listening you should be able to hear what is there. Because so much is available to the ear for hearing, it is possible to hear almost anything you want in the rap sound of a great fiddle. So you must want nothing.

Another problem is autosuggestion. This is what occurs when you tell yourself that you are hearing the third or the fifth when what you are actually hearing is the octave. There can be an effective counter to this. Make a suggestion that what is present is a non harmonic pitch. That is, an “overtone'' not in the harmonic series, like a minor third or a fourth. When you find that the sound cannot be interpreted as what you are counter suggesting then you can be more sure that what you are hearing is so. You know that the overtone for that area is the one, when you cannot make it disappear or reorient itself. What I do is to think the pitch first. By anticipating the pitch and comparing the rap sound with it, you can tell quickly what the pitch is. My guess or pitch anticipation is sometimes in agreement, sometimes in disagreement, either way I learn to know what the scheme is. I always double check my findings by thinking a semitone higher or lower than the pitch that I have already observed. Doing this weakens the potency of autosuggestion.

Another vexing problem is not having a knuckle on your hand which is capable of producing a sound of sufficient clarity. If so, do some experimenting to get the clearest sound audible. When others are present ask them to do the honors by lending a hand and lightly rapping on the fiddle for you. When this is not possible, you can use the eraser end of a new pencil. Be careful not to drop the pencil eraser end down on the surface from too great a height. I recommend dropping it from a height above the surface of a quarter inch or so. When you have to do this, practice a few times on a table top before using it on the fiddle in order to avoid marring the varnish.

Once you have thoroughly examined the tuning on the top, turn the violin over and do the test on the back. Take care to completely damp off the extraneous vibration from the top. Because hands are the most effective dampers for this, when others are present ask them to assist in damping off the top. But, take care. The varnish on the great antique violins is sensitive to warm moist touch from the hands, so protect the varnish from direct contact using a handkerchief or clean dish towel. When the top is neatly damped off check out the tuning on the back. When you have repeated this test on five to ten antique Italian violins you should, I trust, be able to confirm my findings.

Because the area tuning principle is so exquisitely simple, it may prove hard for many people in the making and playing professions to accept it. As the determining principle which accounts for the extraordinary tone quality that the typical great Italian fiddle emits, it stands alone. Neither the varnish nor the wood nor the modeling nor the workmanship can by themselves make a violin built today sound like the best of the 17th- and 18th-century violins. This is already something that everyone knows. History has shown us that aging does not improve the quality of the famous 19th-century violin maker’s products. Likewise, it will not improve today’s output unless the varnish covers wood which has been well wrought and finely tuned.

Lest you think that applying the principle expressed in Area Tuning is too difficult or worse, nonsense, read the article by Elatia Harris in the link below in which she interviews me and there you can hear some sound samples of work done by Pierre Liebe, an amateur violinist and violin maker, who actually documented his initial efforts in area tuning. Below you can hear his before recording followed by two separate track of the after recording, which is then followed by two more after recordings documenting the results of my suggestion that he go back, pop the violin apart and perfect the tuning some more.

In the first sample, he plays his violin before it has been opened so you can hear how the instrument sounds prior to being tuned. In the first couple of sound samples following, you can hear the results of his initial effort. When Pierre sent me these sound samples, he asked me for my feedback. I responded that it sounded like he needed to go back and purify the tuning that he started which was moving in the right direction but needed to be rectified completely. The remaining sound samples followed a week later. You can hear the results for yourself.

If the results sound nonsensical to you then don't bother using the principle. If you think the violin is improved by the principle having been applied to it, then you would be wise to use it. Since this was Pierre's first attempt at doing anything like this, it should prove that this behavior was totally within the grasp of every musical instrument maker in the 16th-18th centuries. It doesn't require an act of genius to apply. The genius of Strad and Guarneri was in how extreme they were in their precision and purity of tuning. They were merely the most extreme in how far they took this idea.

I have learned that any finely-tuned scheme carries with it very important playing qualities. These playing qualities are ease and immediacy of tone production, fullness of tone, freedom of tone, a glowing brilliancy, great purity of tone, strength of tone, great carrying power, flexibility of tone, superior tonal balance, evenness between the strings, seemingly unlimited tonal reserve, richness in the bass and fullness in the treble, and more secure in-tune playing. I have also found that each tuning scheme tends to favor one or more of these playing qualities. Depending on the choice of wood, an 18th century maker would alter the scheme to fill out the spectrum of overtones he or she most preferred. Harder woods tend to emphasize highest overtones so a more concordant scheme (one having fewer dissonant overtones) would be used, while softer woods which dampen the higher overtones might have a more dissonant scheme, thus bringing out the overtones which the wood might leave out. The best instruments by Stradivari and Guarneri are those which marry the tuning scheme which is most favorable for enhancing all these playing qualities to the appropriate pitch, which was determined after considering the wood and peculiarities of the modeling used.

A natural question to ask is, "How does the varnish fit into the picture?'' We know that varnish has the effect of changing the pitch. We know also that the harder the varnish, the stiffer and more resistant it is. Conversely, the softer the varnish is, the more pliable and flexible it is. The ideal varnish is hard, tough, flexible, and pliable. There is still no varnish that measures up. (The statement in this last sentence was true when I originally wrote this article. Now, it is no longer true. Read my article on violin varnish. That varnish measures up when properly made.) When a varnish does not measure up, it has the unpleasant effect of determining in a major way how the violin is going to sound. The role of varnish on an instrument made according to the area tuning principles is one of strict neutrality. It must encourage everything yet dampen nothing. It must contain the energy and integrate the vibration of the plates as they respond “partially'' and “fundamentally.''

Once I became aware that I had discovered something of substance with this area tuning principle, I felt that it was important to find from what source in nature the early Italian violin makers might have derived their inspiration. I discovered what I believe to be that source quite by accident in the shower one day. I noticed that the high pressure water as it struck my body produced distinct pitches. Wondering if there was any relationship between the pitches, I let the flow strike against my body at first in the chest, then on my throat, and so on up my face and head. I found that the various areas in my body corresponded to the changes in mass, density, plane (of surface), and materials. Each area had a different pitch. Moreover, each pitch was an overtone of the pitch of my chest.

For me, this was nature’s confirmation of the principle. In imitating the human voice, they imitated nature’s mode of acoustical construction by following the principle which nature employs in creating the sound of the human voice. The timbre of every voice is the result of these overtones, and the prominence of each overtone is governed by the amount of area allowed to it in the body. (Nature being what it is, infinitely variable, voices will yield different results even when the observations suggest that two voices should be similar. So far, evidence has not been gathered to confirm or deny the hypothesis that the more area that an overtone has allotted to it in one’s body, the more prominent that overtone is in the sound of one’s voice. But reason dictates that this is what is happening.)

While there are other acoustical principles at work in the great Italian violins, not just the area tuning principle, they do not stand to make their effect unless the tuning principle is first observed (applied). It was the knowledge of these principles which constituted the science of the art of violin making as Stradivari knew it. It was a “copyist’s'' attitude which caused this science to be overlooked. Worshipping varnish and expert craftsmanship has created the blindness to these principles. Recognizing “golden calves'' for what they are is the best hope for music in the future.

It has not been my intention to give out formulas or state dogmatic rules. The area tuning principle is neither. It is a wholly different way of looking at violin making. It suggests that the violin makers in Italy viewed themselves not as mere fancy box makers but as builders of sound in a violin format, in imitation of God and His nature. It also suggests that when viewed this way, the process of making a violin of excellence is simple, straightforward, and really unmysterious. The truth of this can only be measured by those of you who become skilled in executing the principles and by the players who use the results capably, moving the listeners with stirring performances of music.

December 2008: Since I wrote this article more than 25 years ago, I have been hoping for some independent evidence that other violin makers have "become skilled in executing the principles and by the players who use the results capably" (taken from the sentence above). I am happy to say that this has finally happened. A few weeks ago, I had the pleasure of hearing a really good sounding violin made by a German violin maker by the name of Stefan-Peter Greiner. Curious to understand why the instrument was so appealing, I tapped on it and discovered that it was clearly and precisely "area tuned". Nothing could have made me happier. Seeing another modern maker's work that employed the area tuning principle was a full confirmation of the validity of the contents of the above article.

Now, it could be that Herr Greiner has come to this result by wholly other means than I myself use. If that be so, more power to him. It doesn't change the end result, which is area tuned. How a maker produces a good sound reliably instrument after instrument can only be accomplished by the application of true fixed principles. What a maker does to realize those principles is largely irrelevant. If Herr Greiner uses careful electronic measurements or works completely intuitively or works systematically or searches for his final result by trial and error, that the plates exhibit clearly tuned areas, which is what I found on his violin (similar to figures 6a and 6b above with minor variants), that is all that matters. A wonderful tasting cake made by whatever means, tastes as wonderful.

When I subsequently went to look up Herr Greiner on the web, I was doubly pleased to learn that some extremely important violinists are using his violins, among them is Christian Tezlaff. And what astonished me was that a Greiner violin was selling for around $40,000.00. This information came from a news site and so some of the information, especially about the price, may be inflated, as is the tendency among popular journalists to enjoy exaggerating the importance of their reports by discussing values placed on art objects, as though that was the test of true quality. Nevertheless, I wish to acknowledge Mr. Greiner's achievement in making a beautiful sounding violin. Now, I can only hope that others will be encouraged by his success in using the area tuning principle, and be tempted themselves to master the use of this principle.

October 2013: I had the opportunity to examine a Samuel Sygmuntowicz Violin made in 1991. That violin was very clearly Area Tuned. Whether or not Herr Greiner or Mr. Sygmuntowicz would actually own that they are Area Tuning their violins remains to be seen. So far, they have not. But that in no way discounts the excellent results that they are achieving in their violins.

You can read the email below which was sent to me by someone who tried the area tuning principle on his violins and sent me this report.

6 November 2013

Dear Mr. Hill,

I thought you might find my "Keith Hill tuning" experiences with two old violins of interest. The first was an old German violin that I got on eBay. It had been coated with spar varnish, or something similar, that caused a horrid orange-peel finish all over the instrument. I had not seen that before I had bought it, or I never would have done so. My first task was to scrape all that off, leaving the original varnish as intact as I could manage. While that was no easy task, I have great experience with scrapers on other fine woods, so the task was not daunting, just tedious. It came out okay.

I had to remove the top to repair a crack. This was my first experience with opening a violin, and I found it to be easy. While I had it apart I took the opportunity to apply some of your techniques of tap tuning, which led me to thin the top and back with appropriate scraping, using your tone patterns from your website as best as my old ears could manage. I made a tape recording of the instrument before I began any work on it. Initially it had a weak, slightly woody sound. I found the insides, especially the back, had not been thinned at all near the edges. It was easy for my old ears to hear the note rise drastically as I tapped progressively toward the edges. And the notes were not the same from side to side within the boundaries set by you.

I really couldn't tell what the pitch, or note, of the taps at the various areas were, but I could tell differences. I could just about discern an octave in the tapped note. What I did was to try to make the tones within a given area, all of which were supposed to be the same tapped note -- per the charts on your website of the front and back areas of the violin -- to in fact be that same note. I did this by scraping to lower the tap note. I was surprised at how little wood removal was required to lower the pitch of the tap note significantly.

I did quite a lot of tapping and scraping. When I got the violin back together I found it was now the loudest of my four violins. I recorded it again with the same strings, and it sounded quite good. The tone was still a bit "woody," but loud, pleasant and commanding. I replaced the rosewood tailpiece with one of ebony, and that improved the sound quality. Now, with Dominant strings and new pegs on it, its sound is at least the equal of my Gemünder Excelsior (#802), and to some ears, it is far more pleasant and commanding. For the record, it's my "Schwarze Diamant" because of an ebony inlay in its back.

Next, I tried the same scraping technique on a second violin, a copy of the Amati from Czecho-Slovakia (sic). This one required some work and finish on its neck, and I made and applied a finish using some sap from a 400+ year-old Ponderosa outside my front door. It came out looking quite nice. But the sound...! The result is an even more powerful violin, by which I mean louder, and with very even volume across the four strings. With a Teller bridge it has a pleasant and mellow sound. (The Gemünder Excelsior has a best-quality Milo Stamm bridge, which might make it somewhat thinner or sharper sounding.) At any rate, I can hardly believe what this simple scraping technique does for violins. It seems to turn inexpensive instruments into jewels with amazing sound, for not a whole lot of work.

Thank you for providing the template for this work, which I find fascinating. I plan to do a third violin, another old German Strad copy that sounds nice but has no volume. We'll see if I can do the trick a third time.

Thank you for your time.

Ray Ordorica/Idaho.

by Keith Hill © 2015

I have purposely posted a photo of a harpsichord because the principle of area tuning applied in some form to every type of musical instrument made during the period between 1450 and 1800. That includes: organs, harpsichords, clavichords, pianos, violas da gamba, violins, violas, cellos, double basses, guitars, lutes, woodwind instruments, drums, brass instruments, in other words, every kind of instrument. The acoustical technology based on area tuning was ubiquitous in Europe because the predominant science of the day was Pythagorean...not modern physics. Pythagorean science is the knowledge of musical ratios and how to apply those ratios intelligently to everything...including buildings. In a time when the idea of noise, an idea we have accustomed ourselves to since the advent of electricity, was people talking loudly and carriages rumbling across cobblestone roads, sound was the leading edge of science and musical instrument making was the counterpart for our fascination with computers today. Musical instruments were THE home entertainment centers of every cultivated home and every intelligent cultured person was expected to be able to play a musical instrument or be left out of social activities within the family. Now we each watch on the computer what we prefer and we are becoming isolated and musically ignorant as a result. We let recordings make our music for us.

Originally published in American Lutherie #1, 1985

In my article Area Tuning the Violin I presented my discovery of one of the theoretical principles governing the acoustical quality of the violins made by Stradivarius and his numerous Italian contemporaries. Because I believe that the area-tuning principle is the most important of all the acoustical principles pertinent to violin making, I deemed it best to present it in isolation.

I would be less than open with you if I did not say that the American Acoustical Society and the Catgut Acoustical Society both rejected the worthiness of the area-tuning principle back in 1984. I feel that their reasons were full of vested self-interest and their own theories based on plate flexibility. I tell you here what I told them: Paying attention to flexibility of free plates is a waste of time and attention. I have recently observed the application of the area tuning principle in the violins of two living violin makers, a Peter Stephan Greiner violin from 2005 and a Samuel Zygmuntowicz violin from 1991, though they would likely not admit to it. In my view, how the effect of the principle happens to occur, the result is the same intended or not but I can assuredly say that the Zygmuntowicz violin was executed purposefully, because I was able to examine the tuning system closely. Because of my respect for what they might consider to be proprietary knowledge, I will not publish their area tuning maps. Furthermore, the dismissive attitude regarding the idea of area tuning that so many violin makers affect, who consider themselves masters of the craft, indicates to me that my original observations made back in the early 1980's, which I took the trouble to publish, have arrived at what I call the "third stage of acceptance" that all new right ideas must submit to.

Those stages are:

1. Utter Rejection (All new right ideas are almost universally rejected), 2.Followed by Ridicule (What doesn't want to go away gets ridiculed in hopes that it will go away.), 3. Dismissiveness (What won't go away is sniffed at as the tide begins to turn in the new ideas direction), 4. Silence (As the evidence piles up against the old conventional ideas in favor of the new idea. This stage involves Mark Twains advice to fools: "It is better to look stupid, than to open your mouth and remove all doubt."), and finally, stage 5. " I KNEW THAT!"(Those who can't fight against the new idea then have to submit themselves to something their brains have utterly rejected and are forced to deal with their inability to recover their professional esteem, or become like dinosaurs --extinct.

Consider the following points.

First, thousands of violins have been made using the notion or theory based on plate flexibility for the last two centuries, yet no consistently superior results have been produced.

I used to test my plates for flexibility but quickly abandoned the practice when it occurred to me that there was no objective measure for flexibility. It seems that something which must depend on muscle tone of the person doing the flexing, which can change from day to day, is highly subjective and prone to mistakes. What the flexor has been doing just ten minute before can influence that test. Those who would input electronic testing equipment into the process are to be made fools of by Stradivarius and his colleagues who needed no such equipment.

Second, making so-called objective measurements of plates (ala Chaladni et al) and doing ex-in situ flexing of plates has very little to do with how the top and back behave in a violin that is set up and playable. Microphones, as good as they may ever be, are incompetent replacements for ears and brains unless those who are doing the hearing with them aren’t connected to either, in which case microphones may indeed be superior to either or both. That not withstanding, microphones are too colored in how they pick up and transmit signals. The diaphragms, wiring and housing all contribute significantly to the signals. And how glitter or iron filings on a violin plate or surface behaves when the plates not glued onto a set of ribs with another plate opposing it nor being stopped someplace off-center of the middle, is acoustically uninteresting. Should acoustic researchers discover a way to make such measurements and take photos of glitter on plates of a great violin while it is being played with a bow by a really good player, then what they come up with might prove to be interesting. As it is, these pseudo-scientific (visually dominant) measures of acoustical (aurally dominant) phenomena are irrelevant at best and not even entertaining at worst. They deceive those who want to learn about that type of acoustics into thinking that they can reproduce the sound of the 18th century Cremonese violins, and delay their own more productive investigations by filling their heads with nonsense.

Last, the amount of distortion that you can subject a free plate to never happens on a playing violin. The notion that the old masters had a "mystical intuitive measure or sensibility,'' seeming to know where to remove wood depending on how the plates flexed, is wishful thinking. The removal of wood must have been methodical and direct for such consistency of result to exist. The area-tuning principle leads the way to a methodical, direct, no-nonsense approach.

At this point, I feel it might be purposeful to add to the discussion some thoughts and hints of a more practical nature specifically for luthiers. It is my genuine interest that those of you who desire to use the Area Tuning principle not be hampered in your endeavors. I hope that what I offer here will contribute to that end.

Hint #1. I cannot urge you strongly enough to use a monochord instead of tuning forks, electronic devices, and so on. I have conducted all of my experiments using this tool. I find the monochord to be more versatile, more reliable, easier to use, better sounding, and less sensually insulting than the other devices. It is more convenient to use because the overtones are so easy to find for any given frequency.

Hint #2. To build a monochord, glue together three pieces of pine or basswood, about 4” x 5” x 40”, using one piece as a bottom and the other two pieces as sides for the box. Fill one end with a block 1” thick. At the other end, cut a 1” end block short by 1/2” , or drill several large holes in it, to allow an air space between the bottom and the block. Glue this block in so that its top edge is flush with the top edge of the sides of the box. This air space will act as the soundhole. For the top, glue to your monochord a 1/8th” thick piece of quartersawn pine or spruce. The box is now complete. When the glue is dry, trim off all excess wood and glue and chamfer the edges in order to make the box pleasant to handle. Then, proceed to pin, bridge, and string it. I use headless nails for hitchpins, zither tuning pins, and .010” hard steel wire for strings. For the nut and bridge I use walnut, but maple will do just as well. The cross section for the nut and bridges should look like a house as seen from the end.

Hint #3. I have two strings on my monochord. One of the strings stays at a constant pitch and acts as a point of reference, removing the nuisance of constantly having to refer to a tuning bar or fork to make sure that my monochord is at pitch.

Technically speaking, a monochord is a musical instrument that has one string, which is fixed at one end and adjustable for tuning at the other end. It has a fixed nut while the bridge at the other end is movable. A third bridge is a classical feature which you can introduce should you desire to redo the experiments and calculations of Pythagoras regarding the overtone series. However, these calculations are readily available in books.

Start by determining the length for the strings at A-440; I use 22 1/2”. Next, the scale has to be plotted out. I use an equal-tempered scale for reasons too complicated to discuss in this article. An electronic device is best for this purpose if it is accurate because it is fast and easy. Move the bridge until the desired note is achieved, then accurately mark that position and label it with the pitch name. Calculation of bridge positions, such as fret scales, is not workable because string tension is a dynamic variable. Because of this variability, it is important to remember to always keep your monochord string at pitch during this procedure. Any slight variances can be troublesome to you in the future.

Hint #4. Use junker violins purchased from your local violin repair shop to conduct your initial experiments in using the area-tuning principle. I think that you will find it easier to start learning to tune the wood on violins that are already complete, but clearly worth nothing. You can pop off the back to scrape away on the inside of the top while it is attached to the ribs. The back, because of the harder wood, is easier to work on when it is off the ribs. Leave the fingerboard on. When you have reassembled the instrument you can hear the results of your work almost immediately because the instrument is finished.

I never bothered to even clean off the glue except in those cases where the instrument turned out well enough to sell. When selling these glorified pieces of junk, don’t ask too much over the price that you paid for them. The idea is to get on with the next experiment using an instrument of fractionally better quality each time. You may have to do five or six experiments before you get results worth selling. Once you do start getting results, turnover is crucial. I used Titebond glue only on my first experiments in order to hear the results as soon after the tuning as possible. I found that I could disassemble the instrument, tune the wood, and glue the violin back together all in the space of four hours. Within five hours I was hearing the results and judging the success of the experiment.

Hint #5. To determine the success of your experiments you must have worthy criteria. I used the functional performance criteria exhibited by the greatest antique violins, as judged by the greatest violinists. These criteria may at first seem vague, but once heard and recognized, they are obvious: 1) Ease and immediacy of tone production. 2) Fullness of tone or resonance. 3) Depth of tone. 4) Freedom of tone. 5) Glowing brilliancy, not to be confused with brightness. 6) Great purity of tone. 7) Transparency of tone or clarity. 8) Solidness of tone. 9) Strength of tone. 10) Great carrying power. 11) Flexibility of tone, the ability of the sound to be altered by the player to create different vowels. 12) Superior tonal balance, that the sound feels complete in every way regarding the proportional relationship of the overtones to the fundamental. 13) Evenness of response between the strings, that the strings speak equally well throughout, letting nothing stand out or be less than it could be. 14) Seemingly unlimited tonal reserve. 15) Richness in the bass and fullness in the treble. 16) That the instrument should give the player the sense that it is easier to play in tune. 17) Finally, what I call the ``distortion resistance effect.''

“The Hill Effect”

Hint #6. What I call the ``distortion resistance effect'' is a phenomenon which I, and others, have observed, and for which I believe I have discovered the reason. The phenomenon is that the strings exhibit unusual resistance to being pressed to the fingerboard. Also, even though the instrument will speak with ease and immediacy, the strings will want to speak the overtone rather than the fundamental. The strings appear to the player to offer a certain physical resistance to the bow pressure. So when players speak of great instruments as being "hard to play'' they mean that they are hard to control. What makes them hard to control is the distortion resistance effect. It requires skill to overcome the distortion resistance effect when playing. Stradivari violins are often observed as being not altogether easy to play even by accomplished players. It is due to the distortion resistance effect, which I also call the Hill Effect as I believe I am the first to correctly link the phenomenon to its cause.

The cause of this effect is related directly to the area-tuning principle. When the wood has been tuned according to the overtone series, the distortion resistance effect will result. Instruments which do not exhibit this effect, yet are tuned, are usually tuned to pitches other than the overtone series. Stainer’s violins, for instance, do not exhibit the distortion resistance effect as intensely as Stradivari or Guarneri violins. His instruments are tuned using pitches like fourths, minor thirds and seconds, and minor sixths, as well as an octave.

The more perfect the tuning of the wood the more resistant the strings will feel. I had a conversation with a violinist from Milwaukee who had the pleasure of playing on Paganini’s del Gesu "Cannon'' in Genoa. He reported to me that the strings were so stiff feeling that he cut his small finger while playing on the instrument for an hour. I would expect that an instrument like the del Jesu “Cannon'' violin would be extremely well in tune. It would help account for why Mr. Paganini wrote as much as he did exploiting the harmonics for his compositions. You can test for this effect yourself by pressing lightly down on to the strings of several violins, including a good old Italian instrument. Because the string lengths are basically the same, the feeling of stiffness should be the same. But it is not. Although Dominant "stark'' strings on a mediocre violin may seem stiff, they are flabby feeling when compared to gut strings on a well-tuned instrument.

Hint #7. When experimenting on finished instruments, you will need to support the plates to avoid breaking them. One solution is to use a thin sheet of foam rubber. It gives firm support broad enough to prevent breakage. Another is to secure the plates for tuning to a workboard which has been cut out in the center. When the plates are placed upside-down in this board, the edges are supported all the way around, leaving the rest of the plate surface to vibrate freely.

Hint #8. You can’t check your tuning accuracy often enough. I check my tuning over and over again at different times just to make sure that it is right. My method is to do the initial tuning as a finishing of the carving-out process. I then glue on the bassbar and tune the plate again. After gluing the top to the ribs, I cut out the f-holes and tune the top yet again. Once the back is glued on, I tune both plates once more on the outside with fine sandpaper. This is the last tuning before the varnishing is started. Once I begin varnishing, there is little to be done to radically alter the tuning. Always allow some time to pass before taking up the plates to check the tuning so that you start with ``fresh'' ears.

When the plates are perfectly in tune according to the scheme that you have worked out beforehand, you can be absolutely sure that the violin will turn out first rate. The principle does all the work for you; all you have to do is be present and exert some effort to that end. I am sure that this is how the 17th- and 18th- century Italians could work so confidently and prolifically.

Hint #9. When the outsides of my violin plates are finished, I place them on a lightbox to carve. My lightbox is topped with a piece of plywood with its center cut out like the workboard. With the light shining from beneath, I can be sure that the wood never gets too thin. The final tuning process is also very speedy. The light allows me to relate wood thickness to color; thicker wood is brown and thinner wood is orange. Wood thickness is also related to pitch; so brown colored wood is higher in pitch and orange colored wood is lower in pitch. The old masters could have used cutouts in the shutters of their workshop windows which would have given similar, if less convenient, results.

Hint #10. Learning is more a process of extracting the ``clearly wrong'' than doing what is right the first time through. Learning, the natural way, occurs when the greatest freedom for making the most mistakes exists; all infants learn language this way. By using our sense of what is right, we can systematically remove those things which are wrong; we need only look. Our attitudes will be the only things preventing us. Learning what to listen for when you knock on the plate of a violin is not easy, but it can be done by everyone who has normal hearing. You must isolate and recognize what all the possible sounds are and ignore everything but that which you wish to hear.

You will hear many things when you use your knuckle to tap on a plate ready for tuning. Use a scraper to tap the plate as well. The sound produced by the scraper will augment that of the knuckle and vice versa. A catalog of the sounds heard will include: the pitch and resonance of the knuckle bone, or the click of the scraper; the pitch of the whole plate; the resonance of the whole plate, i.e., the dying away of the vibrational energy; the pitch of the spot of wood directly under the knuckle or scraper; the pitches of the edges of the plate when held and knocked freely; the pitch of the exact center of the plate, usually a semitone different from that of the whole plate; the pitches of all of the other tunable areas not directly under the knuckle; the pitch of the area being tested (this is what you are most interested in hearing); and the effect of each of these sounds being reflected by the room. If you use a lightbox, you will also hear everything sounding from it. It is not very audible, but you can hear it when you focus on it. What you will need to pay the most attention to will be the pitch of the wood directly under the knuckle. It might be useful to look at how the ear hears in order to focus the attention successfully.

The ear is a wondrous device. It hears everything audible to it. Yet, you rarely ever become confused about what you are listening to. I point out that it hears while you listen. This capacity is both a blessing and a curse. When you desire to, you can focus your attention on the subtlest sensation initiated by the lowest intensity sound in a highly complex stimulus. This is a blessing, especially if you know what you should be listening for. The curse occurs during those times that you are exposed to sound which you have no desire to hear but you are incapable of tuning out.

When you actively tune in to certain stimuli, you equally actively tune out most other things that the ear is, in fact, hearing. The act of tuning-in or tuning-out depends very much on what your preferences are. To refine the sense of hearing demands that you examine your preferences. By preferences, I mean timbres which you like over others, or habits that die hard, or ideas that you might have been working on for so long that they demand that you not put them down even temporarily, or attitudes that you refuse to give up.

Attitudes are curious things. They are the only things which we have absolute control over, yet we rarely exercise that control. As you judge your preferences to determine those of lesser or greater worth and those of lesser or greater significance, your ability to listen clearly will naturally readjust itself according to the priorities that you have established. In effect, you express your judgement and listen accordingly.

If what I have been describing were an easy thing to do, most people would do it. It’s not. It requires months, even years, of intensive and patient scrutiny regarding preferences to achieve clarity of ear, hence clarity of mind. The easy path, though somewhat liable to error, is to replace one preference for another. To use the area-tuning principle, period, you need only prefer to hear it. To use the area-tuning principle masterfully, you will probably have to overhaul your preference system.

Hint #11. The very best way to keep track of how you are doing when tuning the areas is to always be checking the relationships that exist. By this I mean that you will need to watch how the pitch changes relative to the pitches that already exist in the other areas. Tap one of the areas as many as three or four times and then move to another area and tap as many times, always sensing the interval that exists between them.

Hint #12. Most people to whom I say this are very amused. Using the same method of tapping or knocking, tap on your body to discover the overtones that exist on you. All your bone are tuned to overtones of a basic pitch in your body. That pitch resounds when you thump or tap on your breast bone. You clavicle or front shoulder bone usually sounds a 5th above that pitch. This is where the area-tuning principle comes from. Why not hear it first where the hearing is the easiest, that is, on your own body? Each person will have something different in how his or her bones are tuned. The beauty of it is just that. Everyone is different, yet everyone is of equal quality. True, there are some voices that we love to hear; maybe you should knock on those bodies to determine their tuning scheme and use that on your violins. I’m serious!

It is well known amongst singers and voice specialists that these areas resonate but until now no one to my knowledge has defined their specific property of being tuned according to the overtone series. It is hard for me to believe that I am the first person to make this observation, but there it is!

Hint #13. When you tune the wood in any given area on your violin plates, tune each annular ring. To do this, you will require a scraper of small size. Do the tapping with the edge of the scraper. Listen only to the click of the scraper as it hits the wood surface. The frequency of this click is a fifth above the fundamental pitch of that area, an octave up. The scraping sound is also the same pitch as the click, but a bit more difficult to focus on. Tune each ring along its entire length within a given area.

The reason for tuning each ring is that no two rings are alike. Differences in ring density will necessitate differences in wood thickness for the rings. You can circumvent this by selecting wood for homogeneity between the winter rings. Good Luck! I have only found one or two pieces of wood that were homogeneous between the winter rings which I thought would yield a resilient sound; most were too punky. I like resilience more than I like homogeneity of growth. If you do too, then leave the harder rings thin and the softer rings thick.

The ``Art'' of anything is to enhance decent materials by being willing to adapt to any set of conditions to produce the best effect possible. What I have been discussing here are the ``details'' of acoustical craftsmanship. If we are to master our craft, we need to master it at this level.

Hint #14. It’s important to remember that the violin plates are complex because they vibrate freely in some areas and are partly constricted in others, such as the edges and the areas nearest the bassbar. You will need to make the parts near points of constriction thinner because constriction creates stiffness and stiffness equals higher pitch. By making the constricted areas thinner, you make them more flexible and bring them into tune at the same time. Given two surfaces of unequal size, you need to thin the smaller of the two surfaces to make them sound the same pitch. Area size is directly proportional to pitch, given an equal thickness and material. Stiffness is the key factor involved.

To test this phenomenon, tap on a drum head. Tapping from the center to the edge, you will notice that the pitch rises. Were the membrane thinned towards the edge you would get less rise. Doing this thinning causes the membrane to act in unison with itself. This is precisely the effect that you must create on your violin plates. According to my observations of antique fiddles, the mediocre Italian instruments made during the ``Golden Age'' were tuned only in the centers of the areas while at the edges they were left untuned.

Hint #15. Begin tuning by tuning the largest area to the fundamental. Proceed from the largest to the smallest. Should you tune the smallest areas first, you would have to retune everything if you made a mistake on the largest areas; all the pitches of the smaller areas would be out-of-series (nonharmonic).

Hint #16. Once I have determined exactly what frequency I want to end up with, I tune the largest area down to the frequency one semitone higher. I then tune all the areas to that area so that I end up with a completely tuned plate exactly one semitone sharp of my final destination. After this I can confidently go right to the exact and final pitch. This method is very safe.

Hint #17. Accuracy, accuracy, accuracy: This is your goal. Even the pitch you select for an area is not as important as accuracy of tuning. The beauty of the area-tuning principle is that you can make an error pertaining to the pitch, when tuning, without ruining the plate. Simply tune down to the next semitone lower if you’ve gone too far. Although you may not get the exact sound that you were after, you will always get a sound which is resonant, brilliant, open, and free. Who knows, you may even surprise yourself and come up with a tuning scheme that you like better than what you had planned.

Hint #18. Wherever there is a strong curvature in the modeling or a change of direction of curvature on the modeling, you will need to thin the wood at those places. Curvature makes the wood stiffer.

Hint #19. When you are scraping on wood which is perfectly quartersawn, you will need to make that wood a bit thinner than wood which is not, even though the wood is on the same area. Grain at 90 degrees or perpendicular is stiffer, hence, higher in pitch than grain which is 88 or 92 degrees.

Hint #20. Take pains to make the exterior surface of the violin plates as highly polished as possible. The reason for this is that a rough surface dampens the highest frequencies while a polished surface reflects them.

Hint #21. This hint is troublesome to discuss, and I hesitate to discuss it in this article. The reason is that it is esoteric and therefore too easily misunderstood. However, I include it because I feel that without it your ability to understand what I have presented thus far might be impaired. Maybe, maybe not.

To be complete, any art must incorporate three elements. These elements are philosophy, theory, and practice. These correspond directly to the three elements that form our own nature: spirit, mind, and body. Philosophy guides the spirit, while theory guides the mind, and practice guides the body. Usually the mind and body follow in close order after the direction set by the spirit. So the foremost of the three elements is philosophy. For without right attitudes, theory and practice would be subject to much wrongheadedness in the same way that practical techniques become meaningless manipulations when they are unsupported by true theoretical principles. The last 150 years of violin making attest to this truth. So, if the function of philosophy is to guide, ultimately, our actions, then we need to think seriously about the aesthetic act of sensing.

I use the word sensation to mean something specific, but quite different than the conventional usage suggests. I mean sensation of the purist kind, so pure that you can’t prove what you sense much less talk about it. This level of sensation is many times deeper than the mundane variety. It depends very much on how the mind or consciousness is directed. When you direct your attention to what is happening within the sensing mechanism or organ while it is sensing, you can perceive what I mean.

It is sensing with the mind how the experience of sensation feels when sensing is taking place. It is noticing the effect sensation has on the subtler aspects of the sensing organ and seeing how the mind is affected by it. This level is the level I call true knowledge. This is the level at which you know absolutely. You need not interpret, question, or believe with your mind; there is only complete awareness. You can react emotionally to what you sense but you do not need to, necessarily. You have no control over the sensation of sensation. You can only control your awareness of it.

I believe that this level of sensation is absolutely objective. Nothing about it is relative. It is, or it is not. How you feel about it is irrelevant. This level is subject to only one thing, the presence of stimulation. The fact that you can not prove what you ``know'' in no way invalidates the awareness you achieved. It just means that you need not even try to prove what you ``know.'' This level of human experience is wholly free from deception. All other levels are subject to possible deception either from the self or from a source other than the self. Because this level is free of possible deception you can trust it completely.

An exercise for becoming aware of this level of sensation is to enter a totally dark room and, looking into the direction of the light source, turn on the light. At the moment that the light shines, you will sense many things. Be aware of two separate responses in the eye. The stronger of the two is the sensation of the muscle controlling the iris changing the size of the pupil. The second and significantly weaker sensation is the sensation of the effect experienced as the retina is exposed to light. The important idea here is embodied in the words sensation of the effect. This is the root of aesthetic awareness and appreciation. Upon this, all art is constructed. This exercise merely demonstrates in one sensory mode, sight, the level of sensation that I have been discussing.

The question is, so what? What’s so important about this level of pure sensation? The answer is nothing, really. In and of itself, nothing is important. What is important is the effect on the mind that paying attention at this level has over a long period of time.

A mind which is accustomed to being aware at this level of sensation naturally thinks profound thoughts. This is because the step between awareness at this level down to the level of the mind being aware of itself thinking intuitive thoughts is small. This, the final level of awareness, is crucial to our development, both mental and spiritual.

At this level of sensation, we are all reduced to the same experiential status. This is the level which is ``universal.'' Art that is successful, in the ultimate sense, is designed to stimulate in us this level of awareness. We say of that art that it embodies a universal expression. And art which is not fashioned to stimulate us at this level, though popular during its time, will eventually be judged for what it really is.

An Essay: In Praise of Principles. Principles are marvelous. When present, they do their work unobserved. Yet, their effect is very much felt. No good effect is ever achieved without some principle having been applied. What we call talent and genius is really the behavior, which we sense, of some principle being executed. Our senses are designed to respond to effects created by nature and all these effects are the result of some underlying principle. This is why we as natural organisms tend to gravitate to art, which also, in imitation of nature, has effects created by some underlying principle. When a person utilizes a principle we call that person an artist. When we see an artist using principles intelligently, we call the artist a genius. When a child exhibits artist-like tendencies, we say that the child is talented. What sets these individuals apart from others who are involved in similar activities is the acuity of judgment stemming from their awareness of pure sensation and their tenacity regarding the application (either conscious or unconscious) of some principle or principles.

When principles are misapplied, violated, or unused, the effect of the result on our senses is of very non-intense stimulation. The effect seems like so much "nonsense.'' If we are accustomed to "nonsense,'' the effect of the "sensible'' can be almost overpowering. This strength of intensity usually caused the work of the greatest artists in history to be rejected during their own time. Such seems to have been the case with Guarneri del Gesu and Bach.

For many years now, there has been a general trend away from the application of true principles. It was as though they were something to be feared or avoided. They were equated with dogmatisms and rules. They are, of course, neither. However, it was thought (and still is) that principles might inhibit "personal expression.'' Isn’t it ironic that the efforts of those who would deny the use of principles have been largely wasted because the effect of their efforts is that they are unimaginative, lifeless, weak, inhibited, and lacking in interest, quality, or expression, the exact opposite of the effect these individuals desired. Because they failed to employ true principles, and true principles create effects which communicate directly with the senses, their work fails to communicate with the senses.

When we embrace true principles, we find that they do most of our real work for us. All we need to do is be present and expend a little energy to get the job done. Most importantly, our work is done for others, not for ourselves. Because the principles are objective in the effects that they produce, we can be certain that others will experience our work exactly as we intend it.

I believe that artists such as Rembrandt and Guarneri del Gesu were neither talented nor geniuses, as we might think. They were just men who were sensibly aware, who thought deeply about the principles underlying their art, who applied those principles strictly and intelligently, who were unafraid to experiment, and who enjoyed the doing of what they did. Anyone who does likewise would be as great. How could it be otherwise?

with a Condensed Step by Step Description following this Recipe

by Keith Hill

Instructions for Making an Acoustically Proven Varnish

Using only Five Ingredients: Linseed Oil, Rosin, Water, Wood Ashes (Yes, Wood Ashes), and Turpentine

This is a revised reprint of an article I wrote that was published in the American Lutherie, the quarterly journal of the Guild of American Luthiers, Number 37/ Spring 1994. For those of you who may not have access to this journal, I have provided it here for your convenience.

Like many of my fellow Luthiers, I have made numerous experiments in concocting varnishes for use on my violins. I owe a debt of gratitude to earlier experimenters whose work and publications contributed substantially to the outcome. Those whose work contributed materially to the production of my varnish are Ole Bull, members of the 19th Century London Hill Family, George Fry, Jacques Maroger, and Joseph Michelman.

Ole Bull, in his tiny book on the violin, confirmed my instinct that the quality of the great Italian fiddles stemmed from the way all the parts were proportioned and not from the varnish even though the varnish contributes something valuable. He put no stock at all in the magical mysterious marvelous aspects of varnish which many during that time (how little things have changed) were given to worshipping. The books by the Hill family on the makers Stradivarii and Guarnerii provided a meager supply of extremely useful descriptive adjectives for the sounding and playing properties of the instruments by those makers.

George Fry's book describes many varnishes of little real value because his varnishes work neither acoustically nor mechanically. He also discusses the varnishes of other experimenters. One is William Fulton's Oil of turpentine varnish. I use this "Oil of Turpentine" varnish as the basis of my colorants. Should you decide to do so as well, take to heart what he says as his accurate descriptions of what happens when such varnishes are put together show that they can be very dangerous.

Maroger, in his book Secret Formulas and Techniques of the Masters, provides a wealth of information concerning the behaviors of the components of varnishes known to exist in painting during the 17th and 18th centuries.

Joseph Michelman contributed the most because of his belief, which he expressed to me over the phone during my only conversation with him, that the components of ash were the components of the Italian fiddle varnishes. Everything he said made sense to me. Unfortunately, his varnishes don't work very well either mechanically, visually, or acoustically.

Others whose work contributed positively in a negative way presented points of view that accord with the "holy varnish" mentality so common among varnish enthusiasts. They positively presented their beliefs about what the magical ingredient had to be; this helped me reject their avenues of approach. Since this closed many possible paths, they helped speed me on my way.

What I have found will, I hope, be of some use to you in your search for the best possible varnish.

The foundation for my varnish recipe is one simple principle. The violin must be a great sounding violin before it is varnished. If it is not, the varnish will not make it so. The varnish is there to assist in preserving whatever sound the fiddle has, protecting the wood of the fiddle, and enhancing the sound of the fiddle by the effects of its mechanical properties. In other words, the quality of the overall result from the effect of a finished violin is roughly 90% due to the box and how all of its parts are proportioned and the remaining 10% is due to the varnish. When both are right, whatever quality remains wanting comes with playing-in of the fiddle. How good the fiddle sounds depends on these factors. When all factors are at optimum, the result is what we can hear in a Strad or del Jesu fiddle or their equivalent.

Standards for a Useful Varnish

My standards for varnish are, in part, a compendium of traits, characteristics, and properties that have been noted by the above authors. Some are my own. Anyone who is well read in the literature will recognize the sources of the various standards. Here are those standards:

A. It should be easy to make. Easy here is a relative term. I mean that one should not have to be a chemist to make it. That is, almost anyone should be able to throw it together with reasonable success.

B. The ingredients must have been and still be easily obtainable by anyone without significant effort. No unusual ingredients must be present. All the ingredients should yield, upon spectrographic analysis, a reading similar to the findings published by Michelman in his latest articles on Ash Varnishes.

C. The varnish has to exhibit the following optical properties: 1.) dichroism-changing color depending on the angle of sight, 2.) absolute transparency-no apparent loss of light when it enters the varnish and when it leaves the varnish, 3.) uniform refraction-no matter at what angle you view the fiddle the light must not be diminished, 4.) magnification of wood substructure-an effect from light being uniformly distributed within the varnish such that every detail of the wood becomes obvious to the eye, 5.) naturally deep color-one that comes from the depth of color of the various ingredients, 6.) radiant color-the effect of certain components in the varnish that make the color extremely vivid, 7.) extreme effect of depth, h.) significant darkening with age yet never becoming fully dark brown to black but always appearing golden in whatever hue it finally becomes.

D. The varnish has to have the following physical and mechanical properties: 1.) the film should be extremely thin, 2.) the film should be extremely even and without runs or sags, 3.) the film should adhere fast to the previous coat yet maintain the integrity of each individual coat-it may not "melt" or dissolve the previous coat to ensure solid adhesion, 4.) the varnish should be made of ingredients that yield the lightest possible film-the varnish should not weigh down the plates which need to vibrate freely, 5.) the film must be curable only in the sun, 6.) the film must allow itself to be worked into a very high polish easily without being ruined easily. 7.) the film must be a self healing, that is, film nicks and scratches should eventually disappear without any human assistance unless they are too large, 8.) the varnish film must be capable of shrinking in all directions equally as it dries and cures, 9.) the film must be able to "sink" significantly into the surface as it ages, 10.) the varnish should never crack or check, 11.) the film, when dry, should be soluble in alcohol but not in turpentine, 12.) the liquid varnish should improve with age-getting clearer and more luminescent the longer you keep it, 13.) it should never "spoil" on the shelf--it should have an indefinite life so long as the container has not been left open. It should never thicken further, nor should it film over in the container, nor should it cure in the container.

My violin varnish fulfills every criterion stated above. If you share these standards, this recipe will interest you.

Here are the materials you will need: